Achieving Excellence: Ensuring Precision and Accuracy in Steel Metal Stamping

2024-03-13

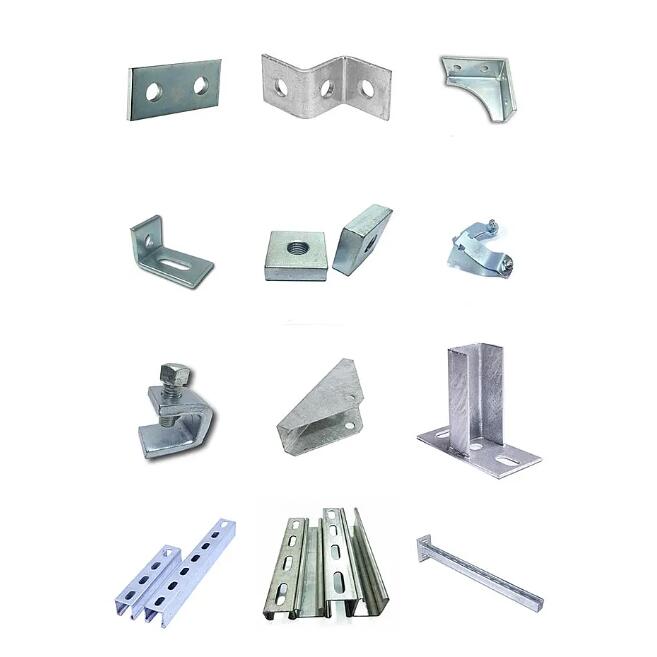

Steel metal stamping is a highly precise manufacturing process that involves transforming flat sheets or coils of steel into intricate components with tight tolerances and complex geometries. Precision and accuracy are paramount in stamped steel components, as they directly impact the performance, functionality, and quality of the final products. In this blog, we'll delve into the key strategies and techniques employed to ensure precision and accuracy in steel metal stamping processes, highlighting the critical steps and considerations involved.

Understanding Precision and Accuracy:

Precision refers to the consistency and repeatability of measurements or operations, while accuracy denotes the degree of conformity between a measured or calculated value and the true or accepted value. In steel metal stamping, achieving both precision and accuracy requires meticulous attention to detail, advanced manufacturing technologies, and rigorous quality control measures.

Key Strategies for Precision and Accuracy:

1. Advanced Tooling and Equipment:

Utilizing state-of-the-art stamping presses, dies, and tooling is essential for achieving precise and accurate results in steel metal stamping. High-quality tooling designs, precision machining techniques, and sophisticated die technologies enable the creation of components with tight tolerances and complex features.

2. Tight Process Control:

Implementing stringent process controls and monitoring systems throughout the stamping process is crucial for maintaining precision and accuracy. Parameters such as material thickness, feed rates, punch and die alignment, and press speed must be carefully controlled to ensure consistent part dimensions and geometries.

3. Material Selection and Preparation:

Choosing the appropriate steel material and ensuring its uniformity, cleanliness, and consistency are critical for achieving precision in metal stamping. Proper material selection, including the choice of steel grade and thickness, helps optimize formability, reduce springback, and minimize dimensional variations in stamped components.

4. Die Design and Optimization:

Designing and optimizing stamping dies to minimize deflection, distortion, and wear is essential for achieving precision and accuracy in steel metal stamping. Advanced die simulation software, finite element analysis (FEA), and prototyping techniques are employed to optimize die designs and predict stamping outcomes accurately.

5. Tooling Maintenance and Inspection:

Regular maintenance and inspection of stamping tooling are essential for preserving precision and accuracy over time. Periodic checks for wear, damage, and dimensional deviations help identify and rectify issues before they affect part quality. Proper lubrication, cleaning, and sharpening of tooling components ensure consistent performance and longevity.

6. In-Process Quality Control:

Implementing robust in-process inspection and quality control measures at various stages of the stamping process helps detect deviations from specifications early on and prevent non-conforming parts from entering the production stream. Automated vision systems, coordinate measuring machines (CMMs), and statistical process control (SPC) techniques are utilized to monitor part dimensions, tolerances, and surface quality in real-time.

7. Continuous Improvement and Feedback Loop:

Establishing a culture of continuous improvement and feedback is vital for enhancing precision and accuracy in steel metal stamping. Analyzing process data, identifying root causes of deviations, and implementing corrective actions lead to incremental improvements in process efficiency, quality, and overall performance.

Conclusion:

In conclusion, ensuring precision and accuracy in steel metal stamping requires a combination of advanced technologies, meticulous process control, and a commitment to quality excellence. By employing strategies such as advanced tooling and equipment, tight process control, material optimization, die design and maintenance, in-process inspection, and continuous improvement, manufacturers can achieve exceptional levels of precision and accuracy in stamped steel components. As a cornerstone of modern manufacturing, precision metal stamping contributes to the production of high-quality, reliable, and functionally superior components that drive innovation and excellence across industries.