Essential Pretreatment Steps for Copper Powder Before Silver Coating

2024-05-27

In the process of coating copper powder with silver, several pretreatment steps are crucial to ensure a uniform, adhesive, and durable silver coating. These steps not only improve the coating quality but also affect the final performance and application of the silver-coated copper powder. Let's explore the necessary pretreatment steps and their importance.

Pretreatment Steps for Copper Powder

Step 1: Cleaning

Before any coating process, it's essential to clean the copper powder thoroughly. This step removes impurities, dirt, and oxide layers that can interfere with the coating process. Common cleaning methods include rinsing with deionized water, using solvents, or a combination of both.

Step 2: Surface Activation

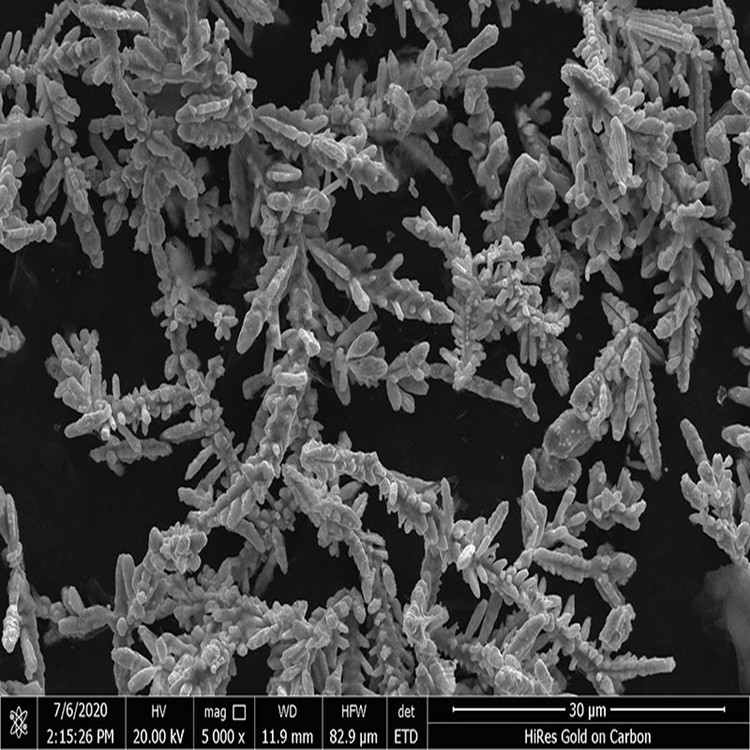

Surface activation prepares the copper powder for better adhesion of the silver coating. This step typically involves treating the copper powder with an acid or oxidizing agent to roughen the surface or create an oxide layer. The roughened surface provides more anchor points for the silver coating to adhere, while the oxide layer can promote chemical bonding between the copper and silver.

Step 3: Drying

After cleaning and surface activation, the copper powder needs to be dried thoroughly to remove any residual water or solvent. This step is crucial because moisture or solvent residues can negatively impact the coating process and final coating quality.

Why Are These Steps Necessary?

Ensuring Adhesion

The pretreatment steps are necessary to ensure good adhesion between the silver coating and the copper powder. Without proper cleaning and surface activation, impurities and oxide layers can prevent the coating from adhering evenly and securely to the copper particles. This can lead to coating defects, such as peeling, cracking, or uneven coating thickness.

Improving Coating Quality

The pretreatment steps also improve the overall coating quality. By removing impurities and roughening the surface, the coating can penetrate deeper into the copper particles, resulting in a more durable and uniform coating. The oxide layer created during surface activation can also promote chemical bonding between the copper and silver, further enhancing the coating's adhesion and stability.

Enhancing Performance

Ultimately, the pretreatment steps enhance the performance of the silver-coated copper powder. A uniform, adhesive, and durable coating improves the powder's conductivity, corrosion resistance, and other critical properties. This allows the silver-coated copper powder to perform better in applications such as electronics, sensors, and energy storage devices.

Conclusion

The pretreatment steps for copper powder before silver coating are crucial to ensure a high-quality coating and optimal performance. By thoroughly cleaning, activating the surface, and drying the copper powder, we can promote better adhesion, coating quality, and overall performance of the silver-coated copper powder.