From Shells to Quicklime: The Production and Extraction of Shell Calcium Oxide

2024-07-02

Shell Calcium Oxide, also known as quicklime, is a versatile compound derived from the calcium carbonate found in marine shells. This substance is valued for its wide range of applications in industries such as construction, agriculture, and manufacturing. In this blog, we'll explore the process of producing and extracting Shell Calcium Oxide from shells, detailing each step from the collection of raw materials to the final product.

Step 1: Collection of Shells

The first step in producing Shell Calcium Oxide is the collection of marine shells. These shells are primarily obtained from:

- Seafood Industry: Shells from oysters, clams, mussels, and other shellfish are byproducts of the seafood industry. Rather than being discarded, these shells are collected and repurposed for calcium oxide production.

- Natural Harvesting: In some cases, shells may be collected directly from marine environments. However, this method requires careful consideration of environmental impacts to ensure sustainability and avoid overharvesting.

Step 2: Cleaning and Preparation

Once collected, the shells undergo a thorough cleaning process to remove any organic material, debris, and impurities. This step is crucial to ensure the purity of the final product. The cleaning process typically involves:

- Washing: Shells are washed with water to remove dirt and organic residues.

- Sterilization: To eliminate any remaining organic matter and bacteria, the shells may be sterilized using heat or chemical treatments.

- Drying: After cleaning, the shells are dried to remove moisture, making them easier to process in subsequent steps.

Step 3: Grinding

After cleaning and drying, the shells are ground into a fine powder. This increases the surface area of the material, making it more efficient to convert into calcium oxide. The grinding process involves:

- Crushing: Shells are initially crushed into smaller pieces using crushers or hammer mills.

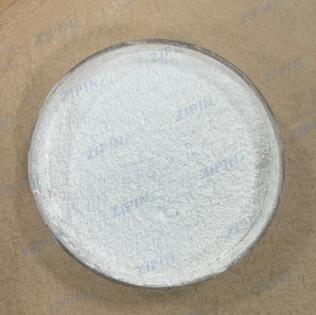

- Milling: The crushed shells are then milled into a fine powder using ball mills or other types of milling equipment.

Step 4: Calcination

The ground shell powder is then subjected to a high-temperature calcination process. Calcination is the key step in producing calcium oxide from calcium carbonate. This process involves:

- Heating: The shell powder is heated in a kiln or furnace at temperatures ranging from 900°C to 1000°C (1652°F to 1832°F). This high temperature causes the calcium carbonate (CaCO3) in the shells to decompose into calcium oxide (CaO) and carbon dioxide (CO2).

Step 5: Quality Control and Packaging

The final step in the production process is quality control and packaging. This ensures that the Shell Calcium Oxide meets industry standards and is safe for use. The quality control process includes:

- Testing: Samples of the calcium oxide are tested for purity, chemical composition, and particle size.

- Packaging: Once the product passes quality control tests, it is packaged in bags or containers for distribution and sale. Proper packaging helps prevent contamination and ensures the product remains effective during storage and transportation.

Conclusion

Producing Shell Calcium Oxide from marine shells involves a series of well-defined steps, from the collection and cleaning of raw shells to the high-temperature calcination process. By repurposing shells from the seafood industry, this production method offers a sustainable and efficient way to create a valuable compound with numerous industrial applications. As the demand for environmentally friendly and sustainable materials continues to grow, Shell Calcium Oxide stands out as a prime example of how natural resources can be utilized responsibly and effectively.