How the Carbon Pipe Extrusion Line Enhances Precision and Productivity

2025-06-13

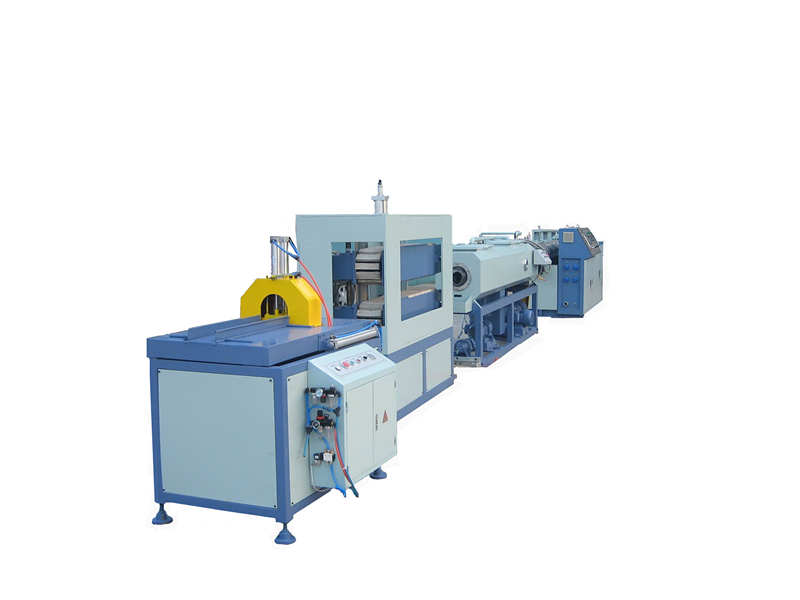

The Carbon Pipe Extrusion Line is a high-performance production system specifically designed for the efficient manufacturing of spiral-reinforced carbon tubes. Engineered with advanced polyolefin processing technology, this extrusion line incorporates a high-efficiency screw extruder capable of delivering exceptional plasticizing performance and steady material flow. The system is built around a separation-type mixing screw and a precisely engineered structural head, which together ensure that the resulting pipes have smooth inner and outer surfaces—an essential requirement for both functional integrity and aesthetic quality.

One of the key advantages of this line is its specialized sizing and cooling system, which adopts a high-efficiency water pump and finely calibrated spray head. This setup achieves rapid and uniform cooling, enabling high-speed extrusion without compromising pipe quality. At the same time, the copper screw caliper sleeve features an optimized design with a pre-cooling inlet and an integrated powerful suction mechanism, helping stabilize the pipe shape and surface finish during the initial cooling stages.

The system's strong flexibility and material compatibility make it suitable for co-extruding two or three layers of polyolefin-based spiral-reinforced tubing in various specifications. Whether for industrial wiring conduits, protective casing, or high-durability construction applications, this line can accommodate a wide range of production needs. Furthermore, the extrusion line is equipped with adjustable motor control and 3D positioning features, greatly improving operational efficiency and making fine-tuning more intuitive for production staff.

Overall, the Carbon Pipe Extrusion Line offers a streamlined, energy-efficient, and user-friendly solution for pipe manufacturers who demand consistency, speed, and versatility. Its integration of advanced material handling, thermal control, and multi-layer extrusion capabilities positions it as an ideal choice for modern pipe production facilities aiming to meet growing market demands.