Innovating with Paint-Dipped Grating: Unveiling Its Practical Applications

2024-07-25

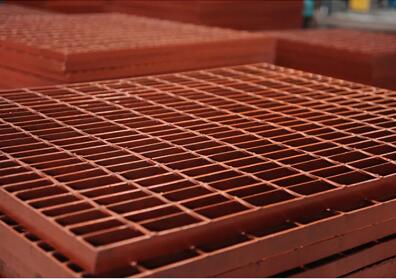

In the world of industrial and architectural design, innovation often arises from the convergence of traditional materials with modern technologies. Paint-dipped grating represents a prime example of this synergy, offering practical solutions across a spectrum of applications where durability, safety, and aesthetic appeal are paramount.

Technological Advancements

The process of creating paint-dipped grating involves advanced techniques in surface preparation and coating application:

- Surface Preparation: Grating materials, typically steel or aluminum, undergo rigorous cleaning and treatment processes to ensure optimal adhesion of the paint coating. This step is crucial for long-term durability and corrosion resistance.

- Coating Application: Modern paint-dipping methods utilize automated systems to ensure uniform coverage and thickness of the paint or powder coating. This precision application not only enhances aesthetic appeal but also maximizes the protective properties of the coating.

Benefits of Paint-Dipped Grating

1. Durability and Corrosion Resistance: The primary advantage of paint-dipped grating lies in its ability to withstand harsh environmental conditions, including exposure to moisture, chemicals, and UV radiation. The paint or powder coating acts as a barrier, preventing corrosion and extending the lifespan of the grating.

2. Customization Options: Designers and architects have the flexibility to choose from a wide range of colors, textures, and finishes to achieve specific design objectives. This customization capability allows for seamless integration of grating into diverse architectural and industrial settings.

3. Safety Features: Anti-slip additives can be incorporated into the paint formulation to enhance traction on grating surfaces, reducing the risk of slips and falls in high-traffic areas.

Practical Applications

Paint-dipped grating finds application in various industries and environments:

- Industrial Settings: Used for flooring, walkways, and platforms in manufacturing plants, chemical facilities, and offshore platforms where safety and durability are critical.

- Architectural Design: Integrated into building facades, bridges, and public spaces to combine structural support with aesthetic appeal.

- Infrastructure Projects: Utilized in transportation hubs, stadiums, and urban redevelopment projects to provide robust and visually appealing solutions for pedestrian and vehicular traffic.

Conclusion

Paint-dipped grating exemplifies the evolution of materials in meeting the multifaceted demands of modern construction and design. By leveraging advancements in coating technology and design versatility, this innovative solution not only enhances the performance and longevity of structural elements but also elevates the visual aesthetics of built environments. As industries continue to embrace sustainable practices and design innovation, paint-dipped grating stands poised as a versatile choice for architects, engineers, and designers seeking to integrate functionality with contemporary design sensibilities.