Navigating Brilliance: Design Considerations and Restrictions with TG250 PCBs

2023-12-14

Introduction:

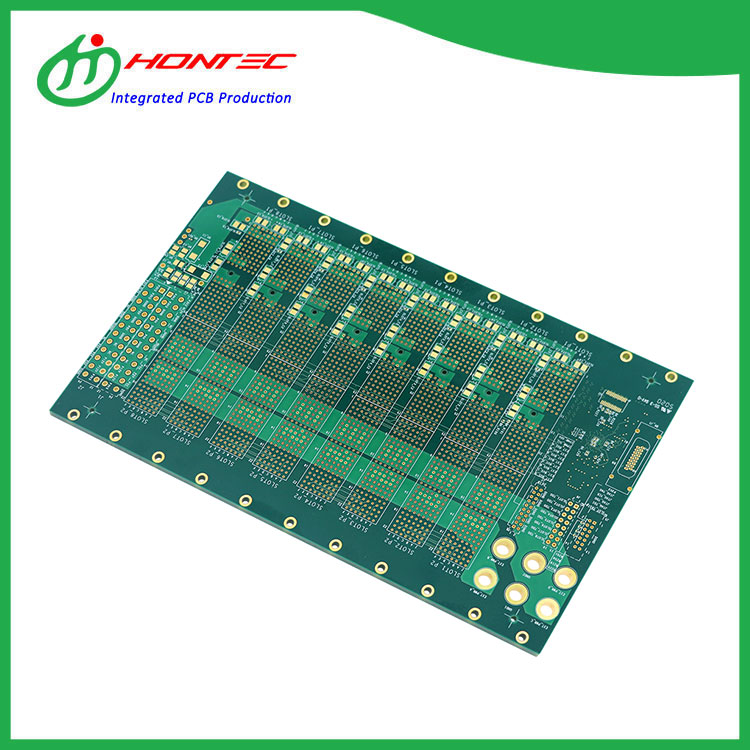

Printed Circuit Boards (PCBs) form the backbone of modern electronics, and the choice of materials plays a pivotal role in their performance. TG250 PCBs have gained recognition for their unique properties, but like any material, they come with specific design considerations and restrictions. In this blog, we will explore the nuances of working with TG250 PCBs, shedding light on the factors designers need to consider for optimal results.

1. Thermal Considerations:

TG250 PCBs boast a high glass transition temperature (Tg), making them resilient to elevated temperatures. Designers must leverage this advantage by ensuring proper thermal management in the layout. Adequate spacing, heat sinks, and well-ventilated enclosures can contribute to maintaining optimal performance.

2. Signal Integrity and Trace Routing:

Given the low dielectric constant of TG250, designers can enjoy enhanced signal integrity. However, careful consideration must be given to trace routing. High-frequency signals may require controlled impedance traces, and designers should pay attention to the spacing between traces to minimize crosstalk.

3. Material Compatibility with Manufacturing Processes:

While TG250 is a robust material, it's essential to ensure compatibility with the chosen manufacturing processes. Designers should work closely with fabricators to validate that the selected TG250 material aligns seamlessly with the chosen manufacturing techniques, such as lamination processes and surface finishes.

4. Stackup Configuration:

The stackup configuration of a PCB is critical for achieving desired electrical and thermal performance. Designers should carefully choose the layer arrangement and thickness to optimize signal integrity and thermal dissipation. TG250's properties can be leveraged to create stackups tailored to specific application requirements.

5. Component Placement:

Strategic component placement is crucial for any PCB design, and TG250 is no exception. Designers should consider the heat-generating components and distribute them in a way that ensures efficient heat dissipation. This can contribute to overall reliability and prevent localized overheating.

6. Environmental Considerations:

While TG250 PCBs are known for their stability, it's important to consider the specific environmental conditions of the intended application. For instance, if the PCB will be exposed to chemicals or moisture, additional protective measures may be necessary to prevent degradation over time.

Conclusion:

Working with TG250 PCBs opens doors to a realm of possibilities, but success hinges on a thorough understanding of the material's strengths and limitations. By carefully considering thermal dynamics, signal integrity, manufacturing processes, and environmental factors, designers can harness the full potential of TG250, creating electronic systems that excel in performance, reliability, and longevity. As technology advances, these considerations will remain crucial for pushing the boundaries of what can be achieved with TG250 PCBs in the ever-evolving landscape of electronic design.