Seamless Precision: Navigating Die Design with Our Intuitive Laser Cutting Software

2023-11-30

Introduction:

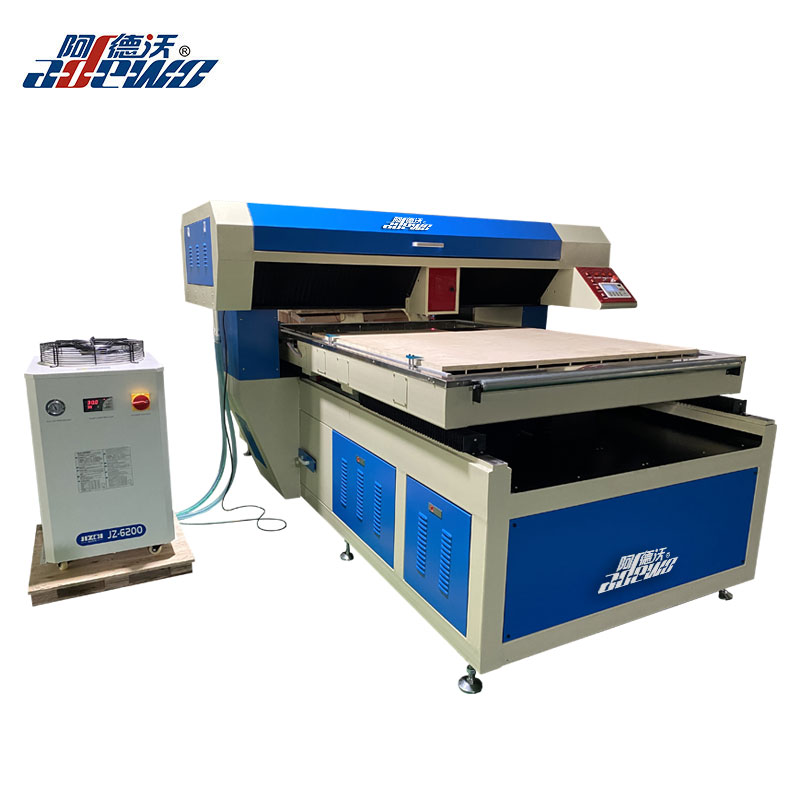

In the fast-paced world of die design and production, efficiency and precision are paramount. Our state-of-the-art Laser Cutting Machine is not just a tool; it's a comprehensive solution that integrates seamlessly with an intuitive software interface. In this blog, we explore how the software interface of our machine contributes to ease of use and efficiency, elevating the die-making process to new heights.

1. User-Friendly Design:

The cornerstone of our laser cutting machine's software interface is its user-friendly design. We understand that not every user is a seasoned expert in laser technology or die design, and our interface reflects this awareness. The intuitive layout and easy navigation empower users of all skill levels to operate the machine with confidence.

2. Drag-and-Drop Functionality:

Gone are the days of cumbersome file transfers and complex setup procedures. Our software interface features drag-and-drop functionality, allowing users to effortlessly import design files into the system. This streamlined process minimizes downtime and ensures a swift transition from design to production.

3. Digital Design Integration:

Seamless integration with popular design software is a hallmark of our machine's software interface. Whether users prefer CAD, CAM, or other design tools, our laser cutting software effortlessly accommodates digital design files. This interoperability ensures a smooth workflow, reducing the need for time-consuming file conversions.

4. Real-Time Design Preview:

Visualizing the design before it hits the production floor is a game-changer. Our software provides a real-time design preview, allowing users to inspect and fine-tune their designs on the screen. This not only enhances precision but also minimizes errors, contributing to a more efficient and error-free die-making process.

5. Parametric Design Capabilities:

Die designs often require precise parameter adjustments. Our laser cutting software enables parametric design capabilities, allowing users to dynamically modify parameters such as cut depth, speed, and power. This flexibility facilitates experimentation and refinement, ensuring that each design meets exacting specifications.

6. Customization for Efficiency:

Recognizing the diverse needs of die makers, our software interface offers customization options. Users can tailor the interface to display relevant information, shortcuts, and tools based on their specific workflows. This level of customization not only enhances efficiency but also contributes to a more personalized and enjoyable user experience.

7. Automatic Toolpath Generation:

Manually generating toolpaths can be a time-consuming task. Our laser cutting software automates this process, generating optimal toolpaths based on the design parameters. This automation not only saves time but also ensures that the machine follows the most efficient routes, contributing to overall production speed.

8. User Training and Support:

To further enhance ease of use, our company provides comprehensive user training and support for the software interface. Whether it's on-site training sessions, online tutorials, or a responsive support team, we are committed to empowering users with the knowledge and resources needed to maximize the capabilities of our laser cutting machine.

Conclusion:

In the realm of die design and production, the efficiency of the tools at your disposal can make all the difference. Our Laser Cutting Machine, coupled with its intuitive software interface, is not just a technological marvel but a partner in precision and efficiency. From user-friendly design to real-time previews and parametric capabilities, our software interface is crafted to elevate the die-making process, ensuring that every design is a masterpiece of efficiency and precision.