What are the advantages of using mesh conveyor wire belts over other types of conveyor belts

2023-10-31

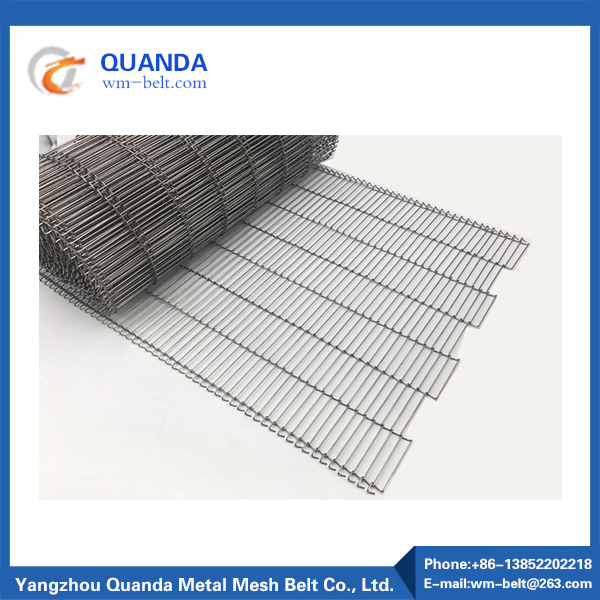

Mesh conveyor wire belts offer several advantages over other types of conveyor belts, making them a preferred choice for specific applications. Some of the key advantages include:

1. Open Mesh Design: Mesh conveyor wire belts have an open and permeable design, allowing for excellent airflow and drainage. This feature is particularly advantageous in processes where products need to be cooled, heated, or dried efficiently.

2. High Temperature Resistance: Many mesh conveyor wire belts are made from materials like stainless steel or Inconel, which can withstand extreme temperatures. This makes them suitable for applications involving heat treatment, baking, and drying.

3. Corrosion Resistance: Stainless steel and other corrosion-resistant materials used in mesh belts make them ideal for applications in industries where exposure to moisture or corrosive substances is common.

4. Easy to Clean: The open mesh design makes cleaning easier, which is essential in industries with strict hygiene requirements, such as food processing.

5. Durability: Mesh conveyor wire belts are known for their durability and long service life, especially when properly maintained. They can withstand wear and tear in heavy-duty industrial applications.

6. Customization: These belts can be customized to match specific application needs, including different mesh sizes, belt widths, and materials. Customization allows them to meet unique requirements.

7. Non-Stick Surface: Some mesh belts made from materials like PTFE (Teflon) have non-stick properties, which are advantageous in industries where products might adhere to the belt surface.

8. Flexibility: Mesh conveyor wire belts are flexible, which allows them to navigate around pulleys and convey products through curved paths more easily than some rigid belt types.

9. Reduced Product Damage: The open mesh design minimizes contact with the belt's surface, reducing the risk of product damage during transport.

10. Reduced Energy Consumption: Improved airflow and reduced friction can lead to energy savings in certain processes, such as drying or cooling.

While mesh conveyor wire belts offer numerous advantages, it's important to note that their suitability depends on the specific application and industry. Choosing the right type of conveyor belt involves considering the unique requirements and challenges of the process in which it will be used.